Reducing Operator Trips Through Integrated Compressor Control

- Dustin Symes

- Jan 7

- 2 min read

The Problem

In natural gas production and processing facilities, operators routinely lose 5-15 minutes per trip walking between standalone compressor control panels and central plant control systems. During compressor startups, process upsets, or troubleshooting scenarios, operators may make dozens of these trips per shift which translates into hours of lost productivity, delayed responses to alarms, and increased safety exposure in extreme weather, trip hazards, or hazardous areas.

Why This Happens

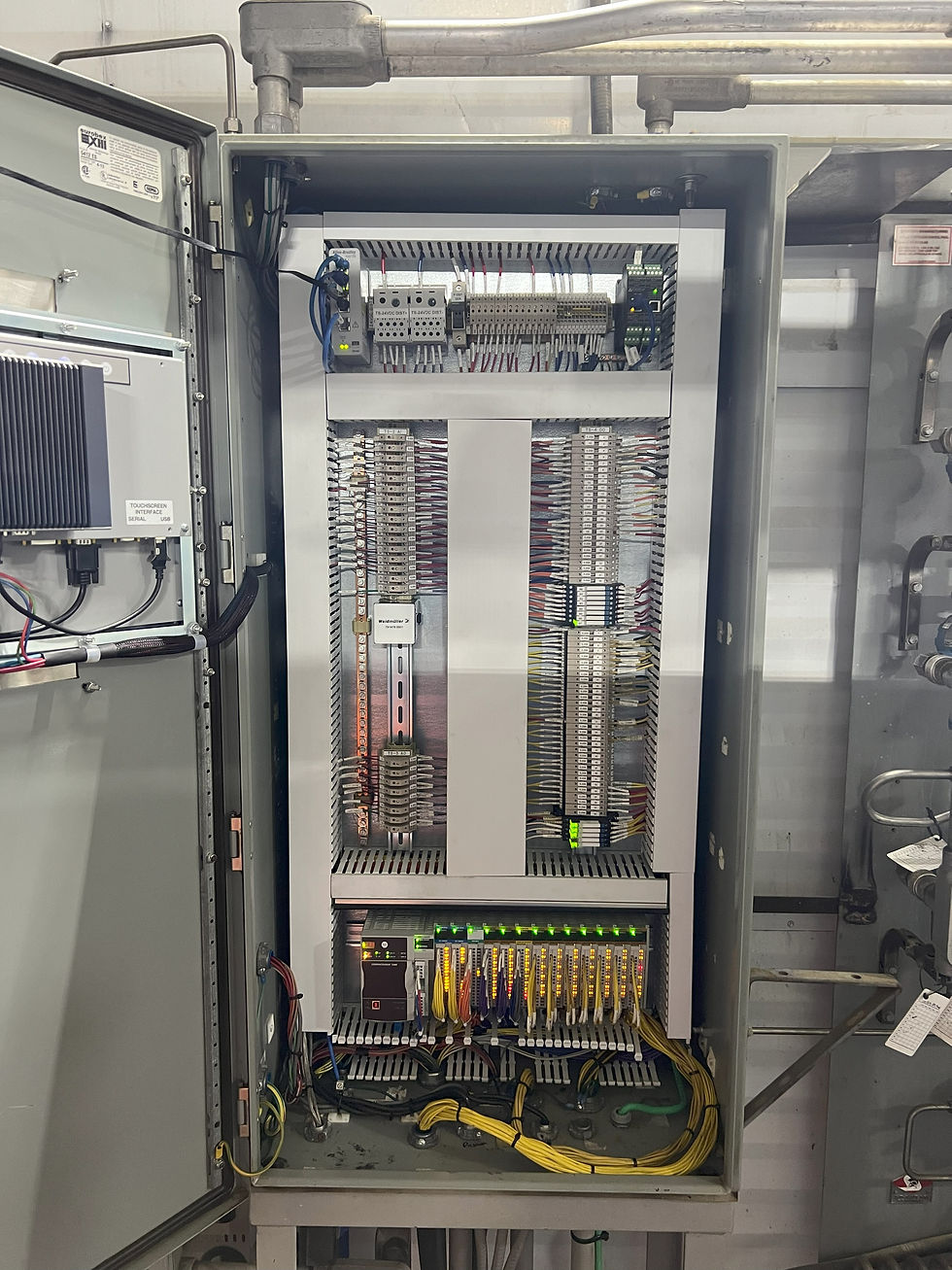

Compressors are critical assets in oil and gas operations. They boost gas pressure for pipeline transport and drive refrigeration processes that liquefy products like propane and LNG. Because compressor applications are relatively standardized, most vendors supply packaged PLC control panels designed to operate as standalone systems.

These panels excel at their primary function: controlling the compressor. Operators use the panel's local HMI to start, stop, and monitor the machine. But the panel exists in isolation from the broader plant control system. When a process upset occurs elsewhere in the facility during compressor startup, the operator must physically leave the compressor building, walk to the main control room or plant HMI, resolve the issue, acknowledge-reset, then return to complete the startup sequence.

Our Solution

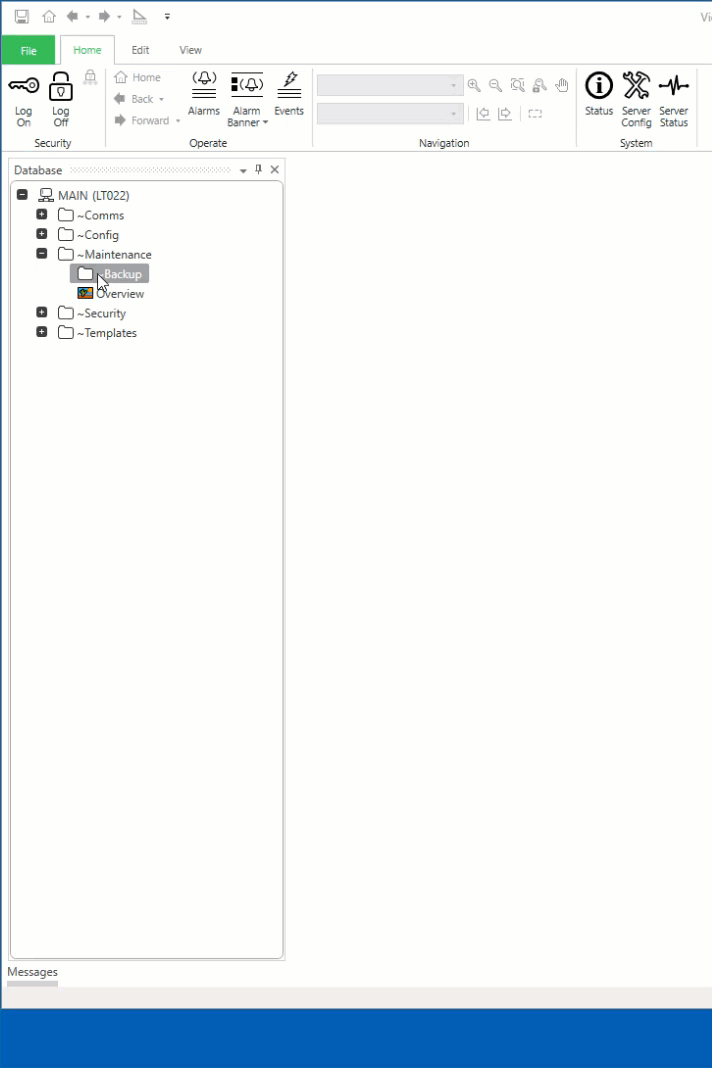

JPI's Advanced Compressor Control Solution is designed for full plant integration from the beginning. While maintaining complete standalone functionality for safety and reliability, our compressor panels can be integrated directly with the plant SCADA/HMI system.

This architecture provides:

Plant-wide visibility at the compressor Operators can see all their plant screens at the compressor. They can monitor and respond to process upsets, alarms, and control actions across the entire facility without ever leaving the compressor building

Remote compressor control Operators can see the complete compressor screens on the plant HMI. They can start, stop, and adjust compressor settings from the central control room, eliminating trips to the compressor building for minor adjustments

Unified Trending and Historical Data Access Typical compressor panels have limited historical capability. Historize points from the compressor panel directly into the HMI historian. Save time by avoiding additional engineering time mapping tags from the compressor system to the plant system for historical data access.

Unified user management and logging Give the right access to the right people and keep track of what is being done. Using full HMI software enables advanced user access and logging of events that is difficult or impossible to achieve with a typical machine HMI panel.

Unified alarm management All compressor and plant alarms are visible on both systems, reducing response time and improving situational awareness.

The Impact

For facilities with multiple compressors or complex process interactions, this integration eliminates hours of operator travel time per shift. Beyond productivity gains, integrated control reduces:

Response time to process upsets and alarms

Safety exposure from trips in extreme weather or hazardous areas

Startup delays and production losses from coordination issues

Operator workload during abnormal situations

The result is measurably more efficient operations with the same headcount.

Comments